WINNEMUCCA MUD

Standard Grind:

MAGNESIUM LIMESTONE

ANIMAL FEED ADDITIVE

GUARANTEED ANALYSIS

CALCIUM (CA) MINIMUM 20%

MAGNESIUM (MG) MINIMUM 10%

Winnemucca Mudd is a type of dolomitic limestone formed thousands of years ago. It differs from other deposits of similar chemical make-up in that it has a different physical structure from most commonly found dololmitic deposits. When mined, the ore is infused with hydrogen sulfide, which is released when processed. Chemical analysis shows Winnemucca Mudd to consist primarily of carbonates: 54% Calcium Carbonate and 45% Magnesium Carbonate.

As nutritionist for one of the larger dairy feed manufacturing companies in Southern California we have been confronted with solving numerous production problems of our many dairy customers. Some dairymen come to us plagued with milk fever in their freshening cows, others with a history of constant acetonemia problems, and others with breeding problems, and still others with calving and “cleaning’ after calving”. Some need higher butterfat test. Some need higher solids-not-fat, and others just need more total milk production. All these problems of our customers become the responsibility of the nutritionist to solve and assist in overcoming and preventing.

Over the years of association with herds of both dairy and beef cattle as we worked on nutritional problems, we have noticed a diarrhea condition in some (but not all) animals in the herd, particularly when being fed heavy grain (high energy) diets. Extensive laboratory examinations proved this condition was one not caused by the many common causative agents such as (1) bacterial or virus infection; (2) lack of sufficient retention material such as texture of feed or coarseness of hay or other roughage; (3) the consumption of physical cleansing agents such as Epsom Salts, Glauber Salts, Mineral oils, etc.; nor (4) the presence of Molybdenum or other toxic materials. The problem of which I speak is readily noticed by the milker inasmuch as both milk production and butterfat test is depressed according to the degree of diarrhea or firmness in the droppings. This amply shown when running a daily production and butterfat testing program. This results is a lowering of both for the herd results. This we term as “cycling”. Explanation of the cause will be given later.

A review in the development of feeding ruminants will best illustrate our feeding concepts. Initially our cattle industry, endeavoring to produce more milk, butterfat and/or meat, started by feeding grains along with the pasture, hay or ensilage. In the meantime as industry developed the processing of foodstuffs their by-products became available for us to feed —initially with high moisture content and then later dehydrated for lower cost transportation and storage. This enabled the addition of higher protein containing materials to the diet as well as the supplementary minerals calcium and phosphorus along with salt. Gradually, through feeding trials, requirements of cattle for growth fattening and milk production was determined. In addition to nutrients requirements, research showed a need for a definite ratio of protein to energy according to the animals stage of maturity and production. Next came findings, under certain conditions or in certain areas, of the need for some of the trace minerals. Some investigators, working with by-products of the dried milk industry, distillers and other fermentative products industries, showed beneficial results over and above their nutrient content when added to the ruminants diet.

In the meantime, both our dairymen and beef cattlemen spurred on as economics dictated have been endeavoring to do a better job of feeding their animals to promote more production of meat, and/or milk at lower cost. In fact, throughout the United States you find many degrees of difference in the progress made in more economical production of milk, butterfat and/or meat. Here on the coast in Southern California feedstuffs and labor are costly—roughage (alfalfa hay) costs $46.00 to $49.00 per ton; milkers wages run from $700 to $ 900 per month; and much of the that is costing from $5000 to $10, 000 per acre. Production costs are high, with some dairies going out of business every week. Most are increasing the size of their herds—ranging from 300 to 800 head milking, with quite a number of dairies milking over 1000 head. Production must be good in order to stay in business. Our rule of thumb is “a minimum production of 50 Ibs. milk daily and 50 Ibs. butterfat monthly”.

Greater understanding of the process of digestion and the many compIex factors that affect digestion was deemed necessary in order to avoid economic upsets in production of milk, butterfat, and or meat. The past decade has shown considerable advance and is continuing to develop more and more knowledge of what and how the digestive processes work within the ruminant. Particular emphasis pertains to the rumen micro-flora. In fact, this has presented to the nutritionist much potential and capability to aid the cattlemen.

The complex four stomach digestive set-up of the ruminant should be considered and handled as an industrial fermentation digestive complex. The reticulo-rumen portion of the digestive tract (commonly known as the paunch) provides an environment that is most favorable for microbial growth (D.C. Church–Digestive Physiology and Nutrition of the Ruminant). The pH (indication of the degree of acidity) in the rumen is slightly acid ranging between 5.5 and 7.0 throughout the entire rumen contents. The normal temperature of 102° F / 105° F is optimum for most micro-flora. The food supply is provided in a more or less continuous manner along with contractions of the stomach helping to bring the micro-organisms in contact with freshly consumed or regurgitated feed. The moist environment and the constant draining-off from the rumen by absorption of the fermentation by-products, as well as passage of material on out of the rumen, provides most ideal conditions for the rumen micro-flora. The kinds of microorganisms vary according to the type of supply of certain nutrients. For instance, Hungate (The Rumen and Its Microbes, 1966) has classified bacteria on the basis of carbohydrates (sugars, fats, fibers, starches, etc.) which each has shown a preference to digest, and partially on the basis of end products produced.

Other nutrients utilized or required by the micro-flora varies among the species, according to Brant and co-workers (Journal of Dairy Science). Ammonia is a prime requirement and may be derived from amino protein degradation or non-protein nitrogen products. In addition many bacteria require carbon dioxide (Church), and some require B-Complex vitamins, both of which are produced by other micro-flora in the rumen. Mineral requirements have been variously defined over the past several decades for the animal and investigators have shown them to be equally as important for the rumen micro-flora. Bryant has shown a need for the following minerals in the diet specifically for various types and species of the microorganisms: Calcium, Phosphorus, Sodium, Potassium, Magnesium, Manganese, Cobalt, Sulfur and Iron. Others have also shown a need for Copper and Zinc.

In artificial rumen experiments, investigators found that feeding rumen fluid invariably promotes an invigorated growth of micro-flora. This has also shown to be advantageous when included in the animal’s diet. In fact, most fermentation products such as by-products of corn processing, distillers’ solubles, B-complex vitamin production residues and even some antibiotic production resides, invigorates or promotes an increased microorganism activity.

Now then, let us return to the afore-mentioned problems of the dairyman and the cattleman and consider possible means of overcoming or avoiding their economic losses. Milk fever, acetonemia and calving problems go back to nutrition defaults. Utilization of minerals as well as energy is dependent upon fermentative conditions in the rumen. Well balanced diets are essential. They must consider not only the nutrient requirements of the animal, but also those of the rumen micro-flora. The close margin for profits over production cost forces us to endeavor to get the most milk production and/or gains for the least cost possible. This, we generally, endeavor to accomplish by more intensive production methods coupled with efficient feeding. Thus better utilization of feeds has become the keynote for the nutritionist.

Initially our attention turns to assisting in the digestion and utilization of the dairy or beef animals’ diet. Then, inasmuch as the main portion of their digestion process is centered with the reticula-rumen area, consideration is given to formulation of the diet to provide not only the nutrients for the animal but also to provide the best possible environment for the rumen microorganisms. The animal provides the optimum temperature for the micro-flora. With its constant muscular contractions, the rumen provides a constant churning and mixing of the media. Saliva for buffering is provided as food passes down the throat to the rumen,—nature’s means of avoiding hyperacidity. The continuous draining off of materials into the blood stream passes nutrients on into the animal for utilization, and helps also to aid in avoiding over-concentration of acids and other needed materials. At the same time a more favorable environment is maintained for the rumen micro-flora. Even the more or less continuous passage of rumen contents on down the digestive tract assists. Thus the nutritionist needs only to regulate the water and foodstuffs intake, including their manner of processing. Grains are ground, cold rolled, steam roiled, flaked, pressure cooked, etc. to release energy. Other materials supply proteins, minerals, chemicals, etc. Even drugs may be used to blend into the media for providing an environment more favorable for microbial activity. These all then enter into the scheme of supplying that which is needed for the animal’s bodily functions for a speeded up production schedule.

Under present day conditions, most feeders are using higher proportions of grain to roughage in the animal’s diet. Considerable effort is being spent in various manners of processing to increase the surface area of the feedstuff to enable greater digestive enzyme action by the rumen micro-flora. Also, others are developing processes to alter the structure of the starch molecules and the fiber particles for greater solubility and availabilty. This enhancement, along with the many other manners of assisting the rumen micro-flora has resulted in a faster break-down feedstuffs than the circulatory system can drain the fermentation products away from the rumen. Under such conditions, unfavorable pathways of break-down takes place. This is where our problem with hyper-acidity starts that eventually results in diarrhea and with the cattle (going off feed).

Many of the rumen micro-flora cannot stand higher degrees-of acidity. Certain ones, however, thrive best under such conditions. “Two such groups, Streptococci and Lactobacilli” states Thomas and Klatte, (Animal Nutrition & Health) ”are the bacteria that produce large quantities of lactic acid which is associated with the acidotic condition.” This hinders the well being of the other microorganisms, and if not stopped, creates such heavy acidity that they not only kill off all other rumen microorganisms, but themselves as well. Thus, when the animal is allowed to eat a large amount of readily fermentable high energy feeds, according to Hungate, “the initial marked increase of Streptococcus bovis is noticed. Then as the rumen becomes more acid, this condition also favors the growth of Lactobacillus Acidolphus resulting in a hyper-acidity fatal to these bacteria as well as all other rumen micro-flora.” This is the condition that nutritionists seek to prevent.

“Luckily the dairy animal seems to be more capable than the beef of coping with the acidotic condition, by her physiological reaction of flushing the gastro-intestinal tract. This condition we recognize as diarrhea.” This gradually depletes the digestive system of the hyper-acidity. Then slowly the rumen microorganisms reinstate themselves, and the rumen fermentation gets back to normal. However, if the diet is not altered to overcome hyper-acidity and the consequent physiological reaction, then the same condition will continue to repeat. This we term as “cycling”. Meantime, the milk production and butterfat test are both depressed.

To avoid hyper-acidity and still push for heavier milk production, numerous studies have been conducted using several chemical additives, antibiotics, and even lowering of energy in the diet. Inasmuch as sodium bi-carbonate is the principal buffer material in saliva, it was theorized that this may be most suitable for maintaining normal rumen function. Its capability has been affirmed to assist in avoiding milk fat depression, however it is unpalatable when used in quantities sufficient to make a noticeable change in the fermentation pathway. Various other buffers also have been tried. Research at University of Maryland by Miller and Hemken conjunction with Waldo, Okamoto, and Moore at the U. S. Department of Agriculture Research Station at Beltsville (Journal of Dairy Science, November) compared three buffers—Potassium Bi-carbonate, Sodium Bi-carbonate and Magnesium Carbonate with each successful in the objective of overcoming the hyperacidity and increasing the butterfat test. The magnesium compound gave the greater response.

Several things in favor of the Winnemucca Mudd mineral compound is that Magnesium is a macro-mineral generally deficient in the animal’s diet. Magnesium carbonate provides not only much needed magnesium but also at the same time provides buffering with its carbonate ion. Magnesium being one of the light weight metallic ions, provides more buffering per pound than calcium carbonate. Then too, when feeding alfalfa hay as is common here in Southern California, calcium is an element that we normally have an excess of in the diet. According to Michigan State researchers, magnesium apparently acts through increased mammary uptake of plasma acetate and try-glycerides.

From a nutritionist’s standpoint, Winnemucca Mudd is most economical to use. Unlike sodium bi-carbonate it is palatable. Winnemucca Mudd does not dissolve in water as does the sodium bi-carbonate. It dissolves only when subjected to the lower undesirable pH at the point where the Streptococci and Lactobaccili start to take over. The needed acidity to dissolve Winnemucca Mudd is only found immediately surrounding the area of carbohydrate break-down. Thus, buffering takes place only as needed and the general enviroment of the rumen contents is maintained at the more favorable pH level for the other rumen microorganisms. Thus greater efficiency can be had from the feeds being consumed. Winnemucca Mudd not only enhances greater utilization of the feed for growth and milk production, but for butterfat production as well.

As for beef cattle, which may be fed even greater quantities of readily of fermentable feedstuffs, Winnemucca Mudd buffering material is equally as beneficial. It is of particular benefit in preventing the severe condition known as Lactic Acidosis, which is associated with “going off feed” and some times results in abbcessed livers.

The dairyman and the cattleman can readily see the results of using Winnemucca Mudd. The droppings can be seen to change from thin diarrhea “slicks” to nice built up “platters” within 3 to 4 days after Winnemucca Mudd is added to the diet. The milker can observe results in milk production in less than a weeks time. Butterfat response takes slightly longer. The beef cattleman will notice his animals will hold on a more constant, heavier grain consumption, which results in from 5% to 10% lower cost gains.

There are many other research data that could be cited. We hope that the information given will assist you in the use of Winnemucca Mudd.

Our recommended rate of use varies from 1.5% to 2% of the grain ration for dairy cattle. Beef cattle, when fed fattening rations of heavy grain concentration, should be fed Winnemucca Mudd at the rate of 2 % of the total diet.

Fred Harshberger

Winnemucca Mudd “is so unique because the ore has hydrogen sulfide (H2S) gas entrapped which is released when it is ground at the mill. Grinding releases the gas and allows it to escape, leaving the final product free of any rotten egg odors. H2S is a very strong reducing agent because it is hydrogen rich; therefore it has prevented destructive oxidative reactions in the rock over the years. The mineral elements are not in the oxide form as they are in most dolomites. Oxidized elements are less available biologically. This is why the calcium, magnesium, and trace elements are so readily available. I know of no other magnesium limestone with these characteristics and properties. Have you ever seen another with H2S entrapped in it? All of the magnesium is in the strict carbonate form whereas many dolomites contain mainly magnesium in the oxide form.”

Sincerely yours,

Daniel C. Loper, Ph.D.

ANNALYSIS FROM AMERICAN ASSAY LABORATORIES

Winnemucca Mudd improves milk production and herd health

Feeding ratios, which include high energy feeds as well as ensiled feeds (e.g. corn silage, haylege, and high moisture grains), can make animals susceptible to a condition known as acidosis. This condition results in reduced feed intake, reduced feed digestibility, undesirable rumen microbial population, dirt eating and other negative affects. The economic loss is reduced efficiency in beef production and lowered butter fat and milk production in dairy cows.

Winnemucca Mudd is an effective feed ingredient for preventing or minimizing the above-mentioned problems. Six to eight ounces per day per animal is the recommended feeding level for dairy and beef cattle.

Winnemucca Mudd is an excellent source of magnesium. Magnesium levels of 0.1% to 0.2% are necessary for maximum performance.

A UNIQUE AND EFFECTIVE FERMENTATION STABILIZER 1. Winnemucca Mudd is a unique source of magnesium calcium carbonate mined in Winnemucca, Nevada. It must not be confused with the other buffering agents on the market. You can use this fact in your marketing efforts to increase sales.

2. Availability of supply is unlimited-you need not worry about shortage, your company personnel can spend their time on more productive activities.

3. Winnemucca Mudd will be strategically warehoused. You can expect excellent service. You need not warehouse large amounts. This saves you warehouse costs.

BENEFITS TO YOUR MANUFACTURER’S CUSTOMERS

1. Winnemucca Mudd exhibits buffering action that effectively works in the PH range in the rumen-this means you can control acidosis and maintain the animals high production.

2. Winnemucca Mudd assists in maintaining feed intake, which results in high production and feed efficiency.

3. Through control of excess acids, one prevents the build up of clostridium perfringes and their toxins.

4. By maintaining normal rumen fermentation, you prevent the build up of Histamines and their effects, i.e. bloat, founder, snotty nose conditions and diarrhea.

5. Winnemucca Mudd gives good return on the cost. The approximate cost per head per day is 1.5 cents. The return needed to justify this cost is: .05 lb. additional gain per day would return approximately 2.0 cents, .30 lb. additional milk per day would return approximately 2.0 cents. Winnemucca Mudd has demonstrated returns much higher than 2.0 cents per day.

DESCRIPTION Winnemucca Mudd is a unique feed grade calcium-magnesium carbonate especially produced to meet the need of the ruminant animal as an available source of magnesium, calcium and carbonate ions, and to fulfill the ever-increasing need for an affective buffering agent. Containing 20% calcium and 11% magnesium.

APPLICATION AND USE

Feeding high-energy foods and ensiled feeds can make animals susceptible to a condition known as acidosis. This condition results in reduced feed intake, reduced feed digestibility, upset of the rumen bacteria and protozoa, decreased butterfat, solids-not-fat and milk production.

Winnemucca Mudd is an effective feed ingredient for preventing the above-mentioned problems. Six to eight ounces per day per cow is the recommended feeding level.

TEST RESULTS

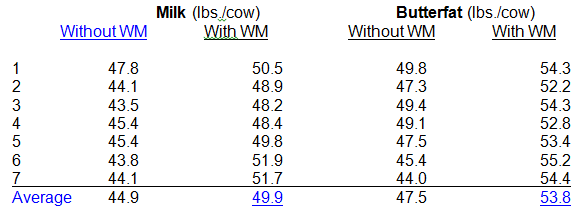

Winnemucca Mudd was evaluated for its effect on milk and butterfat production in a seven-week trial. Two hundred cows were fed Winnemucca Mudd and 80 cows were fed the same ration without Winnemucca Mudd (WM).

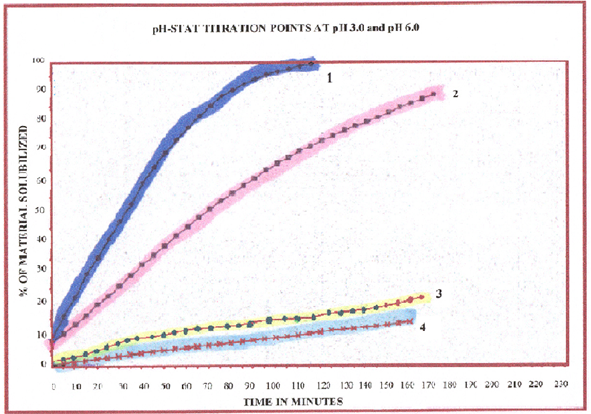

Titration Test

Blue line (number 1) Winnemucca Mudd 3.0 pH

Pink line (number 2) Competitor

Yellow line (number 3) Winnemucca Mudd 6.0 pH

Light blue line (number 4) Competitor